Switching from batch to continuous fermentation system in beer production facilities, can result in significant savings of energy use (approx. 30-35%) and water consumption.

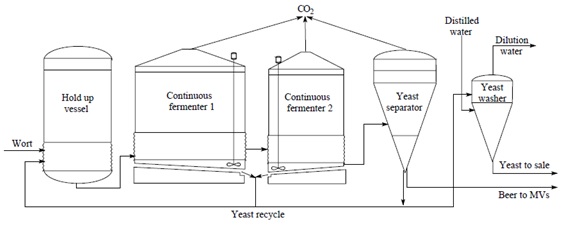

The continuous fermentation system typically consists of three stirred tanks and a fourth unstirred one where the beer is separated from the yeast. The system uses a flocculent yeast strain, which is precipitated and collected at the end of the fermentation. From the fourth tank, the clarified beer flows to a warm maturation tank where the flavour is refined by yeast action. The total residence time is approximately from 40 to 120 hours, depending on production requirements.

The CO2 which is produced during the fermentation process, it is collected from the tops of the fermenting vessels and thus it is not systematically released to the atmosphere. However, CO2 recovery is possible and when purified and compressed it can be used for other processes.