SUEZ and Recyc-Matelas Europe partnered in order to realise and operate innovative facilities to recycle and recover up to 90 % of mattress components, in France (Langon) and Belgium.

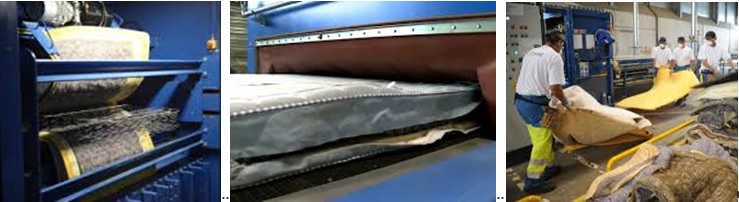

Here it is described the treatment facility operating in Langon (RM Sud-Ouest), inaugurated in June 2015, which is one of the most advanced in Europe (Suez and Recyc-Matelas Europe, 2015). The facility has a treatment capacity of 7 000 tonnes of mattresses per year (30 000 units per month), employs 10 operators and has been realised with a total investment of EUR 1 million. The treatment process is a combination of manual and automated operations. At the reception, mattresses are classified and stored according to their type. Materials not in suitable condition are rejected. The processing method applied is different for innerspring and other types of mattresses. The former are filleted manually and are then processed in specific equipment that separates the innerspring unit from the other materials, which are then separated manually by a couple of operators and sorted by type of material. The innerspring unit is then fed into a steel shredder. The other mattresses are also filleted manually and are then sent to other processing equipment that cuts and sorts the materials. In both cases, after filleting, the mattresses are hygienised by passing them into thermal treatment equipment. All the sorted materials (wool, cotton, felt, PU foam, latex and mixed textiles) are pressed into bales by specific equipment and are then sent for recycling, reaching an average recovery rate of 90 %.

The materials recovered are mostly recycled in the following products:

- textile fibres are reprocessed into construction insulation materials and automotive car mats;

- foams are reprocessed as carpet underlay and cushioning material for the automotive sector;

- springs are reprocessed as metal scrap.

In partnership with the French company Innortex and with the financial support of Ademe, Recyc-Matelas has developed an industrial pilot for producing recycled raw materials from PU foams and textile fibres recovered by dismantling used bedding products, with a capacity of 4 500 t/year (Valormat project, Ademe factsheet, 2013).

Some videos describing the deconstruction process are available at:

- http://www.recyc-matelas.fr/actualite-medias.html

- https://www.youtube.com/watch?v=brXvoIFkHNQ

- https://www.youtube.com/watch?v=JjGVQ8bEIU4

- http://www.actu-environnement.com/ae/news/process-recyclage-matelas-langon-usine-24760.php4

Further information on SUEZ and Recyc-Matelas Europe is available at:

http://www.recyc-matelas.fr/index.html